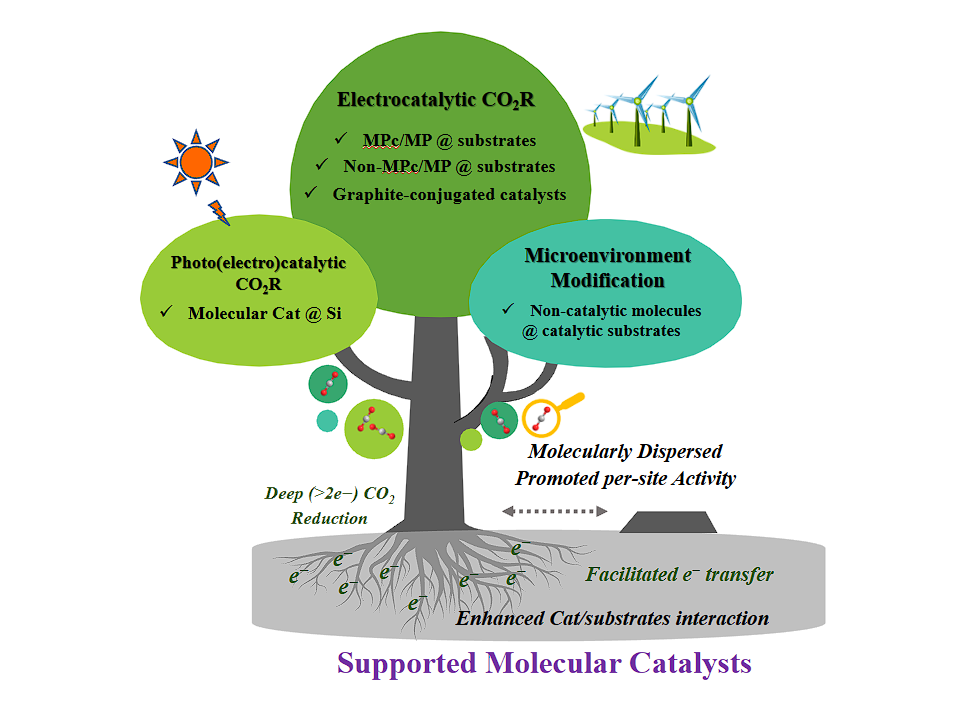

With the proposal of China's scientific development goals of "carbon peak" and "carbon neutrality," the use of green electricity to convert carbon dioxide (CO₂) into value- added products needed for production and daily life (such as syngas, methane, ethylene, ethanol, etc.) through electrochemical catalysis has become an effective technological pathway.

This approach not only achieves efficient "carbon cycling" beyond traditional carbon emission reduction methods but also promotes the upgrading of the energy industry. Based on this vision, the design of efficient catalysts and the study of the mechanisms of electrochemical CO₂ reduction reactions (CO₂ reduction, CO₂R) are particularly critical. In recent years, a large number of molecular catalysts (complex molecules formed by metal ions and organic ligands) and solid catalysts (such as metal and alloy electrodes, carbon and doped materials, MOF/COF novel catalytic materials, etc.) have been designed.

However, most of these are based on ideal laboratory testing conditions, with insufficient consideration of practical issues under industrial production conditions. Professor Nie Weixuan's research group will focus on the bottleneck problems faced by these two major categories of catalysts—molecular catalysts and solid catalysts—under the constraints of actual production conditions and requirements.